Weekly Roundup – 24-Nov-24

DEPG ‘celebrity’ 47077 (D1661, 47613, 47840) ‘NORTH STAR’ was pictured at Grosmont on the North Yorkshire Moors Railway (NYMR) on 20th November 2024 while resting ‘on shed’ during a snowstorm. Photo by Josh Smith © CC BY-NC 3.0

The WSR re-opens this coming weekend (30th Nov and 1st Dec) with a steam-hauled special running from Bishops Lydeard to Minehead in support of the Christmas Market that will be taking place on the platform at Minehead Station. As the coaches have been at Minehead being prepared for the seasonal services, a steam-hauled Empty Coaching Stock (ECS) movement will precede the first public service, with Class 33 ‘Crompton’ D6575 (33057) at the rear to assist the 8-coach train on the gradients from Minehead as far as Crowcombe Heathfield, where the diesel will uncouple to run back down the hill to Williton. The steam loco will take the ECS to Bishops Lydeard to form the fully-booked Saturday special service (some tickets are available for Sunday – click here for details).

Sister Class 33 D6566 (33048) has been based at Bishops Lydeard for a while and will run to Williton early on Saturday morning, so that the two ‘Cromptons’ can be used for training the drivers and secondmen in the practice of multiple running, where two (or more) locomotives are connected together using jumper cables, so that they can be driven from the leading cab as if they were one high-powered locomotive. Running in multiple only requires one crew, and differs from running in tandem where separate crews are in charge of each locomotive. Adding this capability will open up new options for special trains and will allow for some interesting combinations at gala events.

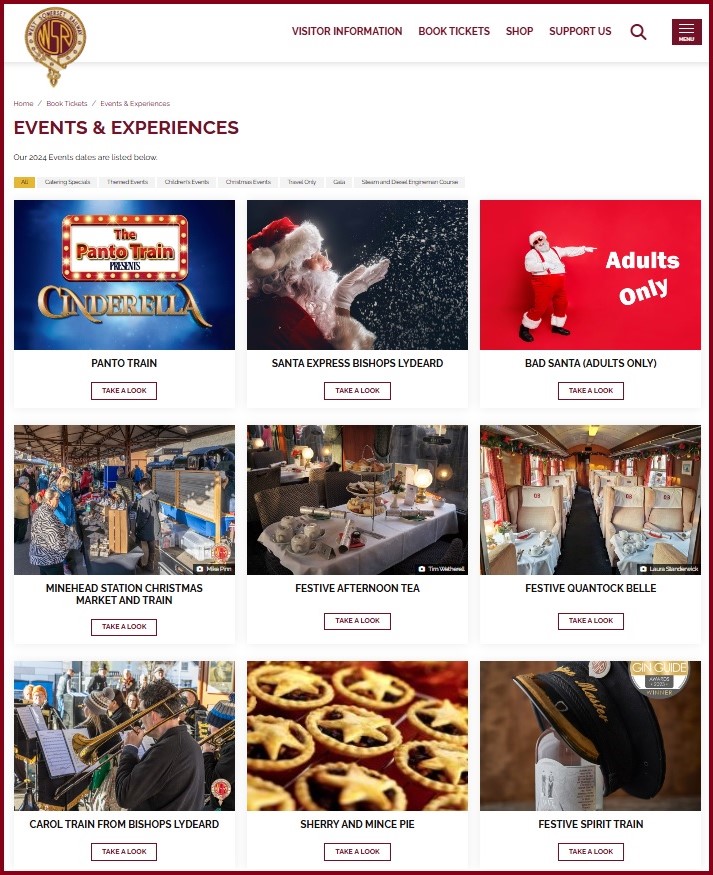

Just a reminder, the format of the Christmas services has changed this year, so our diesels will not be rostered for duty, but they will be on standby and available to provide support if needed. Click here or on the image below to review the new WSR Christmas seasonal offerings:

DIESEL RUNNING DATES for 2025

We don’t yet have the details available for 2025 but we understand that the running pattern will be very similar to that of 2024, so the 2024 DIESEL RUNNING DATES page can be used as a guide, temporarily. Good news – the WSR’s SUMMER DIESEL FESTIVAL has been confirmed as being Thursday 5th through Saturday 7th with a Mixed Traction Day on Sunday 8th of June 2025.

Click here to go to our DIESEL RUNNING DATES page

Click here to go to our ONLINE SHOP

Thank you very much for your support !

LOCO NEWS:

Class 52 D1010 ‘WESTERN CAMPAIGNER’ – the removal of the secondary springs and their associated hangers from the ‘B’ bogie represented another major step forward and was achieved after weeks of effort by volunteers Gordon, David, Tony and Martin, who worked for many hours to prepare and eventually succeed in freeing-up the massive 50mm (2-inch) nuts that control the tension in the secondary spring system.

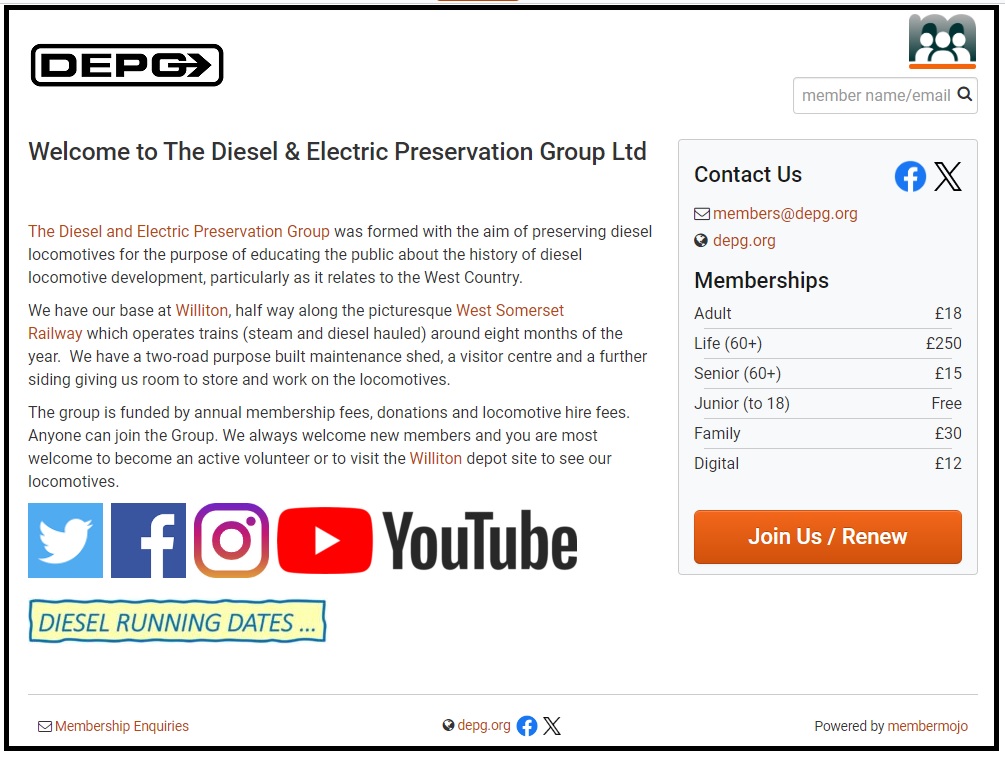

The bogies of the ‘Westerns’ do not have centre pivots because the cardan shafts and gearboxes that power each axle occupy the space that would normally be used for a pivot. Instead, each end of the locomotive is provided with two columns that transfer the weight onto the outer edges of the bogie, as shown in yellow on the photo below (approximately 18 tonnes per column when in operating condition).

The concept of the pivotless bogie was developed by Krauss-Maffei in Germany and licensed to BR who used it as the basis for the ‘Western’ bogies. One such bogie was pictured at Swindon Works in March 1975 and the photo has had yellow arrows added to show the load-bearing pads that carry the weight of the loco body. Photo by R C H Nash © CC BY-NC 3.0

The load is transferred to the so-called ‘elephant’s feet’ bearing plates, then to the bogie frame via the secondary spring system which comprises one huge inverted leaf spring directly underneath each bearing plate and four coil springs on each side of the bogie. The complication is that the whole arrangement must be able to move to allow the loco to negotiate tight curves, so a system of self-restoring rocking pivots is also involved. This not as complicated as it might sound, but it is different to almost any other type of locomotive, the Krauss-Maffei ML4000 being the only other production loco that used this arrangement (the four prototype ML2200s debuted this design, but most other diesel-hydraulics had two-axle bogies).

From the bogie frame, the load is transferred to the axles via the primary springs, which are conventional leaf springs, except that they sit within the bogie frame and are not normally visible (and have already been removed from D1010’s ‘B’ bogie – see the roundup from 01-Sep-24). These springs sit directly on top of the axle boxes, thereby transferring the load to the individual axle and through the wheels to the rails.

As simple as it sounds, the component parts are massive and heavy. The secondary suspension leaf springs each weigh 220kg (almost 500 lbs) and the nuts that are used to set the tension in the springs are 50mm across the flats (2 inches). Add 50 years of rust and dirt, and the result is that they don’t want to come off !

As the photo below shows, where there is a will there is a way, and the application of localised heat causes the nut to expand and relax its grip on the hanger bolt. The individual component parts have now been removed and will be cleaned and inspected, then subjected to non-destructive testing (NDT) before being considered for use again. Any parts exhibiting signs of damage or excess wear will need to be repaired or replaced. Nothing was found to be obviously broken when the parts were being disassembled, so the outlook is good.

MANY THANKS to our volunteers for their efforts and ingenuity, and many thanks to our members and supporters for sponsoring this work and allowing us to make such good and steady progress !

D1010 – the careful application of heat allowed the 50mm (2″) nuts to be removed, releasing the hanger bolts after 50 years of being held in tension. Pictured at Williton on Saturday 23rd November 2024 by Martin Howard © CC BY-NC 3.0

D1010 – one of the hanger bolts is pictured along with the associated ‘knife edge’ parts after being removed from the bogie at Williton on Saturday 23rd November 2024. Photo by Martin Howard © CC BY-NC 3.0

D1010 – one of the caps from the tandem coil spring arrangement is pictured after being removed from the bogie at Williton on Saturday 23rd November 2024. Photo by Martin Howard © CC BY-NC 3.0

D1010 – the tandem coil spring arrangement is now exposed and the guide tube of the right hand spring has been lifted out, revealing plenty of grease (which is a good sign!). These tubes control the lateral movement of the coil springs, ensuring that they remain vertical when loaded. Pictured at Williton on Saturday 23rd November 2024 by Martin Howard © CC BY-NC 3.0

D1010 – the ‘B’ bogie has now had the secondary spring system removed completely, giving a clear view of the centre axle and allowing clean-up work to take place in these otherwise impossible-to-access areas. Pictured at Williton on Thursday 21st November 2024 by David Oswald © CC BY-NC 3.0

D1010 – at the end of the week, a stillage was completely filled with the component parts of the secondary suspension system from the ‘B’ bogie, include the two massive springs. Pictured at Williton on Saturday 23rd November 2024 by Martin Howard © CC BY-NC 3.0

Apologies to those D1010 sponsors who have yet to receive the photos and certificates for the patches that they have sponsored. After ‘almost’ catching up in the Spring, the lifting of the loco and subsequent need to get the bogie overhaul project underway has depleted the resource for the patch engraving and a backlog has built up again, the weather being the latest impediment to progress.

Rest assured that every sponsor will receive their certificate and the details of where to find their sponsored patch. We will be making a further push for funds soon, because we have some big ticket items for refurbishment, including 14 cardan shafts and 32 springs.

MANY THANKS to all who have sponsored and supported the RESTORATION of D1010 !

Class 09 D4107 (09019) – work continues on the repairs and maintenance of this loco, which is now inside the loco shed at Williton. The status of the key tasks are as follows (green = completed, yellow = in progress):

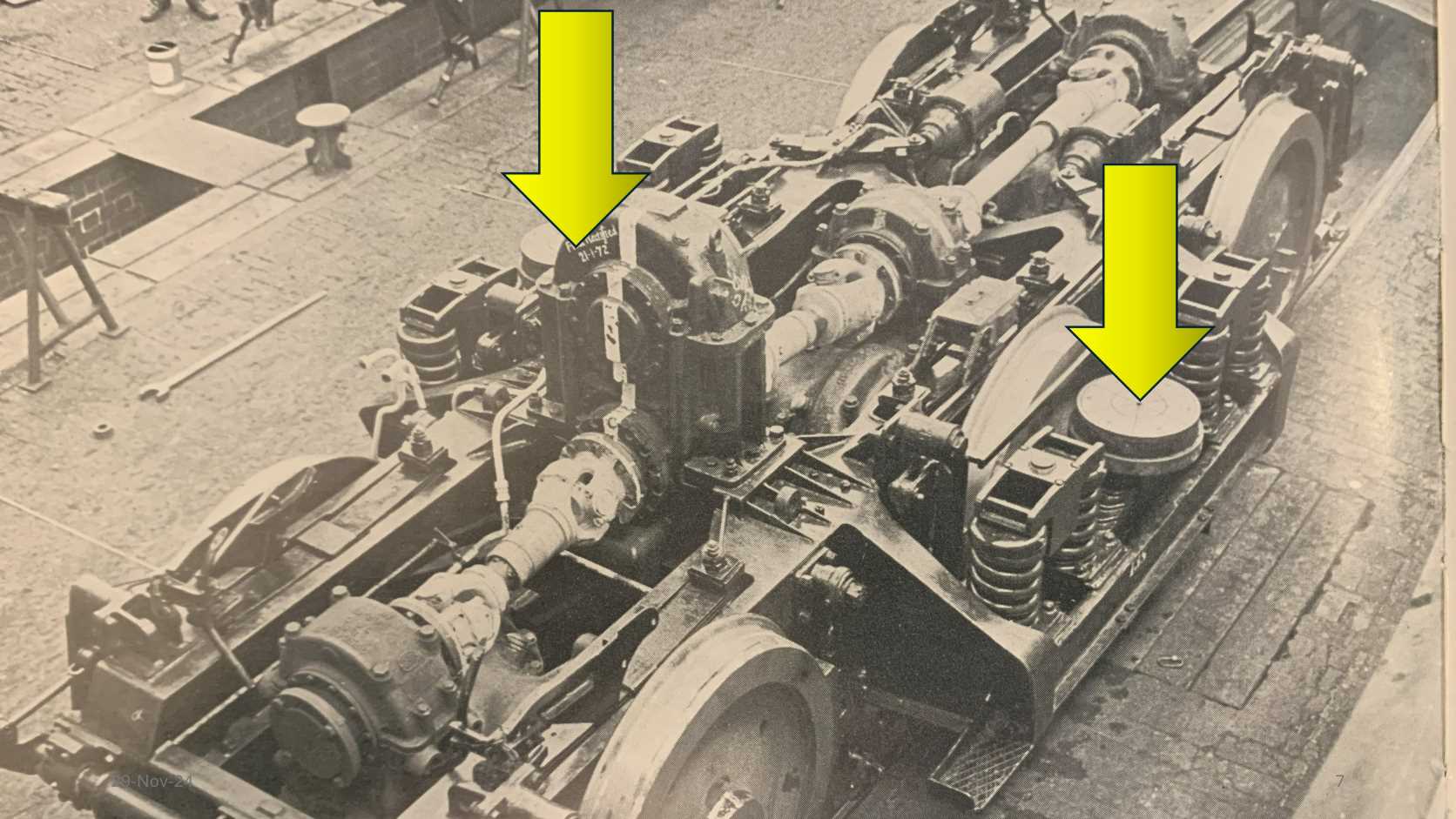

- Repair or replace the Westinghouse 3CV50 compressor due to excessive wear in the pistons and bores.

- The worn out compressor has been removed from the loco. The replacement compressor is of the opposite ‘hand’ and is undergoing alteration to match the loco fittings. The compressor has been separated from the sub-frame which will now be cleaned and painted in readiness for fitting to the new compressor.

- Remove the front ‘Oleo‘ buffers and send them out for overhaul. Clean up the buffer beam and re-paint in readiness for fitting the overhauled buffers.

- Remove the batteries and repair the corroded battery boxes.

- The batteries have been removed, the corroded metal has been cut out in preparation for welding-in of new metal.

- Assess the loco for other bodywork repairs and arrange the repairs as necessary.

- the cab roof requires welding repairs. The cab interior roof lining needs to be removed to allow access. This task will be deferred until the other priority tasks have been completed.

- Inspect the running gear, repair or replace worn parts as necessary.

- Perform scheduled maintenance (engine and auxiliary machines, switchgear)

- Remove the carbon pile voltage regulator, replace with an electronic type.

- The electronic AVR is in stock. The changeover will only take place after completion of roof repairs.

- If sufficient time is available, refresh the paintwork.

Quite a list, but this loco is an essential tool for the WSR so we have a duty to keep her reliable and dependable. She will be returned to Bishops Lydeard in time for the start of the 2025 operating season.

D4107 (09019) – the sub-frame that the compressor sits upon was released from the old compressor and will now be cleaned and painted in readiness for fitting to the new compressor. Pictured at Williton on Saturday 23rd November 2024 by Martin Howard © CC BY-NC 3.0

D4107 (09019) – the front pair of ‘Oleo‘ buffers have been removed from the loco and have been sent out for specialist repair. The buffer beam now needs to be cleaned up and painted in readiness for the return of the overhauled buffers. Pictured at Williton on Saturday 23rd November 2024 by Martin Howard © CC BY-NC 3.0

D4107 (09019) – having removed all of the engine bay doors, we get to see the English Electric 6KT six-cylinder diesel engine that lurks within. This engine design dates back to the 1930s and is noted for its rugged simplicity. Pictured at Williton on Saturday 23rd November 2024 by Martin Howard © CC BY-NC 3.0

Class 33 D6566 (33 048) – this loco will move from Bishops Lydeard to Williton on Saturday 30th November to take part in ‘multiple working’ training for drivers and secondmen. After completion of the training, the loco will return to Bishops Lydeard where she will resume the role of duty loco for that end of the line. The ’33’ will be available to support the WSR Christmas services that originate from Bishops Lydeard, should the need arise.

Class 33 D6575 (33 057) – this loco has been outstationed at Minehead but will return to Williton on Saturday 30th November after performing banking duties on an 8-coach Empty Coaching Stock (ECS) movement. The ’33’ will assist from the rear as far as Crowcombe Heathfield and will then run ‘Light Engine’ to Williton to participate in the ‘multiple working’ training session. The loco will then remain at Williton so that planned maintenance work can be carried out.

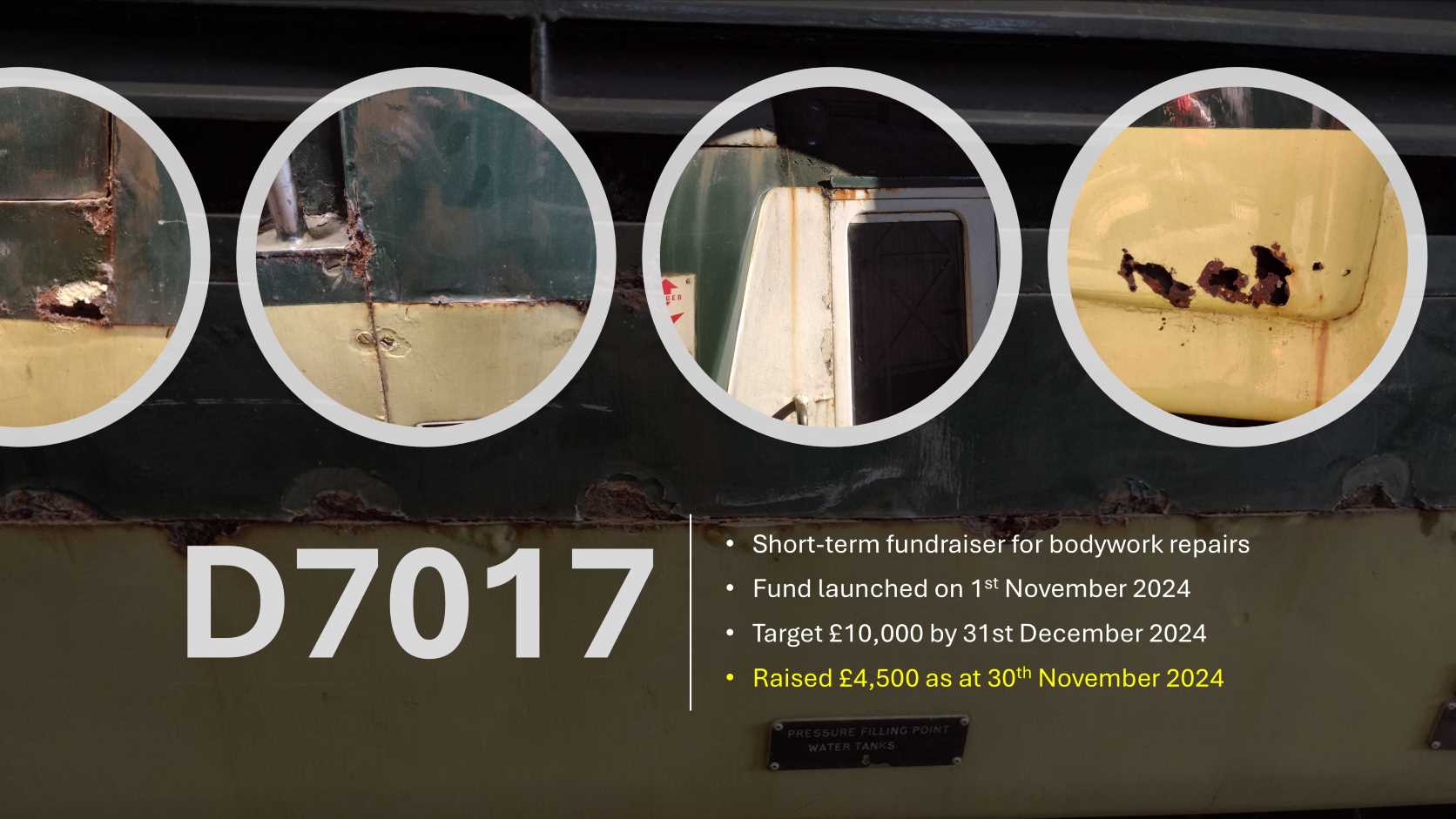

Class 35 ‘Hymek’ D7017 – after launching a short-term fundraiser on the 1st November 2024, we are delighted to announce that the supporters of this wonderful locomotive have already raised more that £4,500 in four weeks, which takes us 45% of the way to our target of £10,000 so THANK YOU FOR YOUR FANTASTIC SUPPORT !

The fundraiser is short-term because the WORK HAS ALREADY STARTED, with the WSR engineering team at Minehead having been contracted to do the repairs. This ensures that the loco receives the bodywork corrosion repairs that she needs before a repaint can be carried out. Although the loco looks quite good from a distance, a closer inspection reveals that corrosion is taking place from behind the skin panels, and this will soon result in perforations and further deterioration. A stitch in time saves nine, which is why we are getting the work done NOW.

Here’s the basis of our appeal for funds:

As the first locomotive to be saved for preservation by the Diesel & Electric Group (the forerunner of the DEPG) back in 1975, Class 35 ‘Hymek’ D7017 has built up a significant following and is very much loved. This loco has had an excellent year, working public service trains on 10 separate days and achieving 100% availability, although she has started to look rather shabby of late. As D7017 is now approaching her 50th year in preservation, it will be appropriate to have her bodywork overhauled and repainted in time for her 50th anniversary, so arrangements have been made to have the work carried out at the Minehead workshops of the West Somerset Railway.

The work involves a number of areas around the body where corrosion has taken hold from the inside and resulted in perforations of the body panels. The metalwork behind the corroded panels will need to be cut out and replaced, so this is not a quick job. The DEPG’s volunteer welders are tied up on other projects that would be unfairly affected by queue-jumping D7017, so the opportunity was taken to follow-up on an offer from the Minehead team and a repair and repainting contract has been agreed. The work has already started and the loco will be back with us in a matter of months so that other maintenance work can continue at Williton.

We need help raising funds for the work that is about to be carried out. This is a short-term appeal so please give this your attention and help by making a donation via our website (click on the icons below) or by bank app or by sending a cheque to the DEPG at Williton. THANK YOU VERY MUCH !

Class 35 ‘Hymek’ D7018 – the ‘transmission team’ have started developing their test setup so that they can perform a functional test on the control block and also confirm that the dog clutches along the gear train are engaging and disengaging smoothly. The hydraulic fluid pressure is being provided by an electric pump instead of the massive V16 diesel engine that is normally coupled to the transmission, and the action of the torque converter is being simulated by a volunteer turning a crank handle one way or the other (accelerating or retarding), according to the presence of the forward or backward blading pressure. The photo below shows a simple LED light system being driven from pressure switches in the ‘WA’ and ‘WE’ pressure lines, which in turn signal the volunteer to apply forward or backward torque. Photos are limited at the moment because the team have their hands full, but a demo is being set up for a week Saturday (7th Dec) and more photos should be available then.

Watch this space !

D7018 – Transmission Team volunteer Tim gets to grips with the crank handle that will be used to simulate the torque converter input to the geartrain of the Mekydro K184u transmission while undergoing static testing. The brightly-lit LED indicates the direction in which to apply the torque. Pictured at Williton on Tuesday 19th November 2024 by Colin Foxhall © CC BY-NC 3.0

Class 14 ‘Teddy Bear’ D9518 – as we get closer to the point where the refurbished cab assembly can be re-fitted onto the loco frames, the effort that is going into the preparation for the lift is increasing. The cab assembly has been rubbed down and painted with primer and will be painted with several more coats before being deemed ready to go back on the loco. The frames have been prepared to receive it and the special ‘Tico‘ sound and vibration absorbing material is close to being delivered, and will soon become the pacing item.

In parallel, work is continuing on the engine overhaul, with the crankshaft now removed for cleaning and inspection. The engine will be the next major component to be re-installed after the cab, so the priority will soon swing in that direction.

D9518 – the cab assembly has now been rubbed down and painted in primer, which is drying slowly in the high humidity that is typical for November. Pictured at Williton on Saturday 23rd November 2024 by Martin Howard © CC BY-NC 3.0

D9518 – the crankshaft of the Paxman 6YJXL engine was lifted out of the crankcase at Williton on Tuesday 19th November 2024. Photo by Terry Deacon © CC BY-NC 3.0

D9518 – the crankshaft of the Paxman 6YJXL engine shows the substantial balance weights that are essential for the smooth running of this 60-degree V6 engine design. Pictured at Williton on Tuesday 19th November 2024 by Terry Deacon © CC BY-NC 3.0

D9518 – the crankcase can now be cleaned up, inspected and prepared for the rebuilding phase, which won’t be far away, given the recent progress. Pictured at Williton on Tuesday 19th November 2024 by Terry Deacon © CC BY-NC 3.0

Quality work needs to be funded, so we will continue to appeal for funds to support the work, right up to the point where the loco is completed. Any surplus will then be used to ensure her proper care and upkeep. If you like what we are doing, please help us by making a donation via our online store (click here or on the image below) or by sending a cheque to the address at the bottom of this email. THANK YOU VERY MUCH FOR YOUR SUPPORT !

Class 14 ‘Teddy Bear’ D9526 – no change – this loco is now stabled outside on Number 1 road at Williton and is likely to remain there until the new year. When space becomes available in the loco shed, she will be going ‘indoors’ for some maintenance work, which will include attention to her engine and her bodywork, to make sure that she is in good shape for the 2025 running season.

Class 47 47077 ‘NORTH STAR’ – this loco is based at Grosmont on the North Yorkshire Moors Railway and has been enduring the heavy snowfalls that are typical of the area (as our opening photo shows). The loco is now in good running order and we hope that she will pick up some work on the Christmas specials, even if only on the empty coaching stock (ECS) movements. We look forward to a very successful 2025 running season !

Andrew Barclay 0-4-0DH 578 – this loco was last in use on Saturday 2nd November for driver training at Williton, resulting in Paul Tucker and Neil McCannon being passed as drivers.

If you can help by donating your time to any of these projects, then please JOIN US and come along to the depot for an introduction to what we do and how we do it. We currently have people on site from Saturday through to Tuesday and we can open on other days if we can be sure of getting at least two volunteers on site at all times, so there is plenty of scope. We have tasks of all types to suit most capabilities, both skilled and unskilled.

Many thanks to all of our volunteers who give up so much of their time to work on the cleaning, painting, maintaining, restoring, managing and fund raising for our fleet of heritage locomotives !

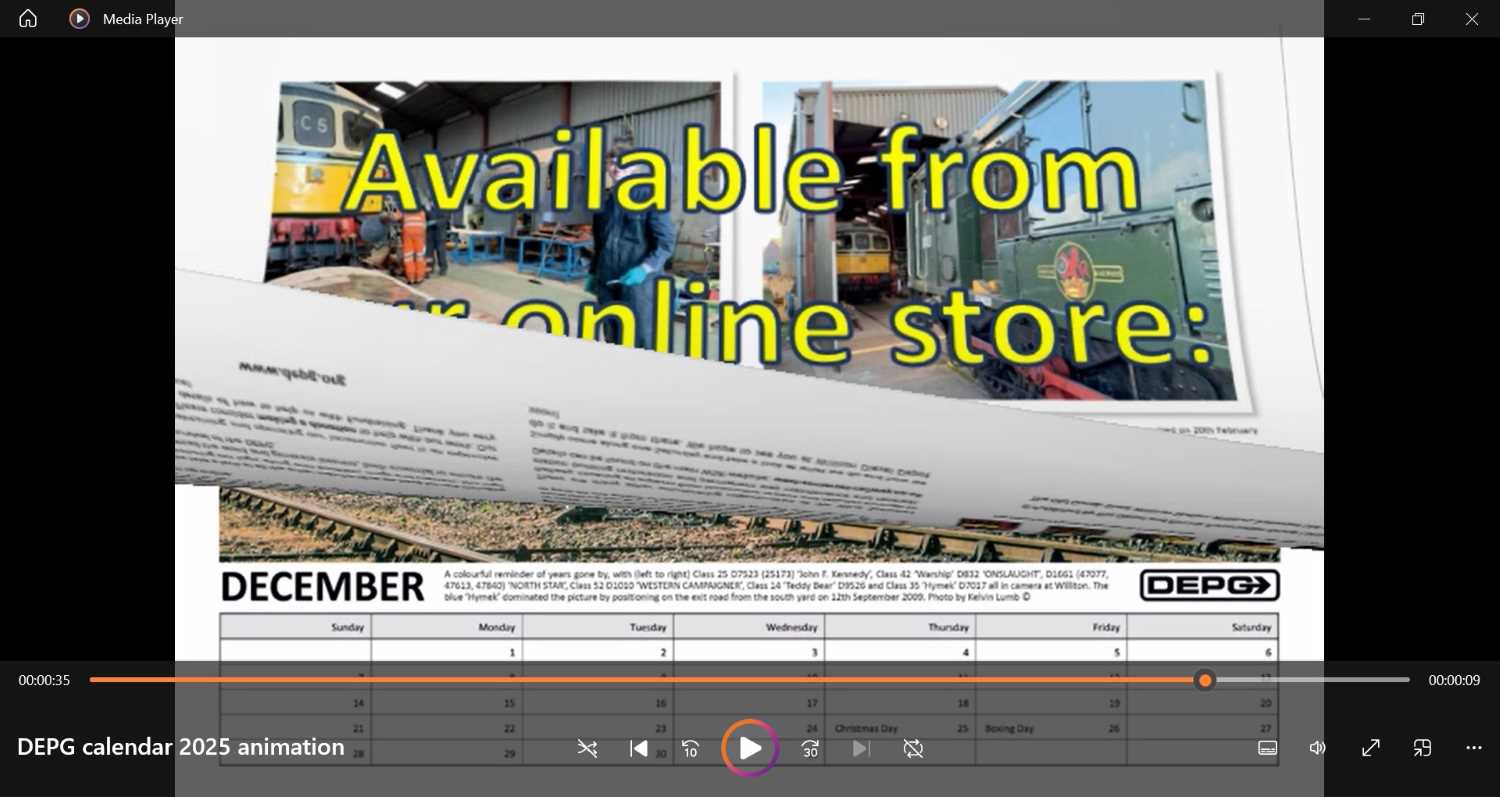

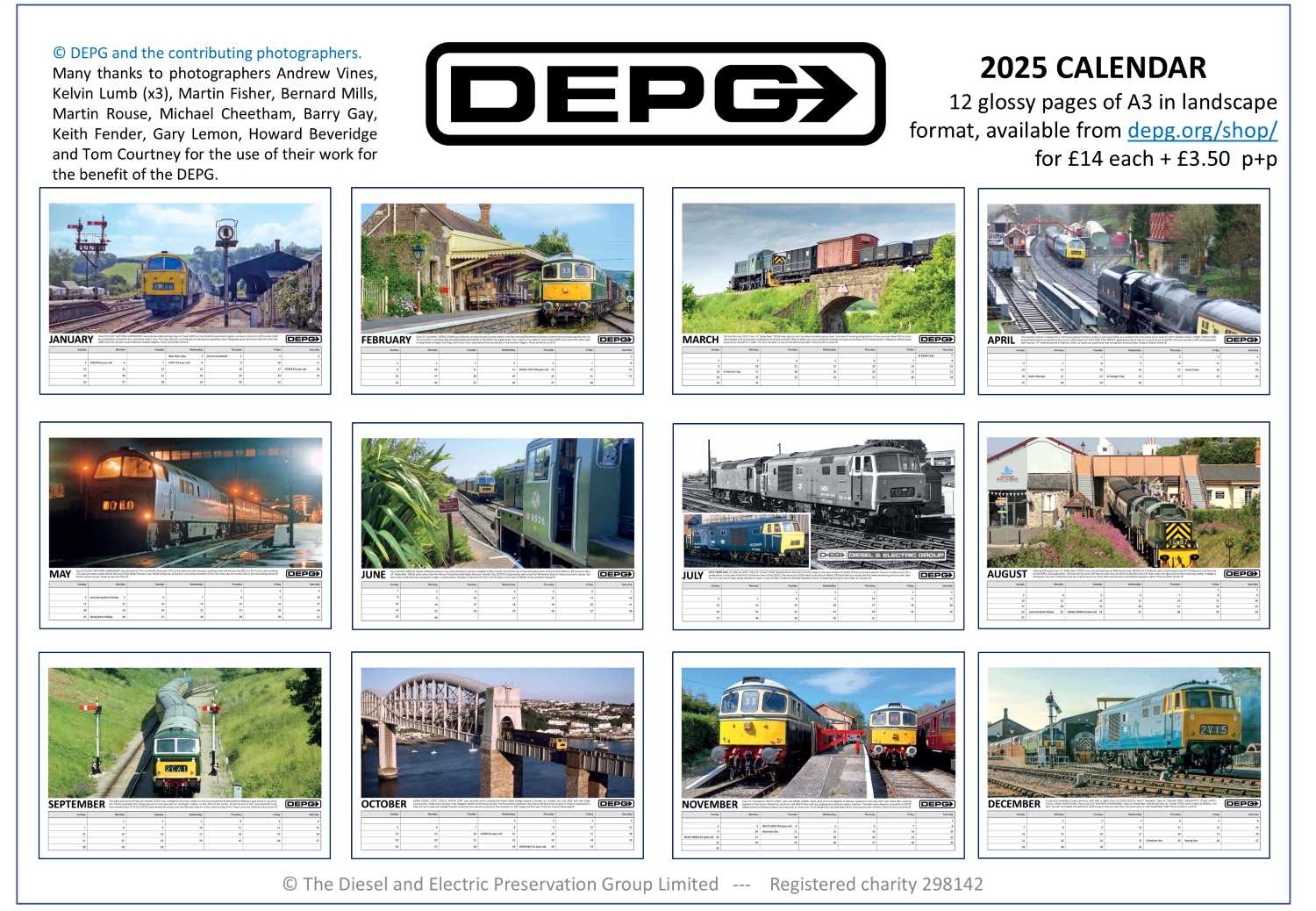

BOOK REVIEW: As the year is quickly running to a close, we need to push the sales of our 2025 DEPG calendar and to point out that stocks are limited and strictly on a first-come-first-served basis.

To give a taste of what is waiting inside the calendar to adorn your walls throughout the coming year, we have put together an animation that flips through the pages. Click here or on the image below to launch the animation:

Alternatively, here is a different presentation with a thumbnail of each page brought together into a single sheet. The actual calendar has one A3 page for each month.

The DEPG 2025 CALENDAR is now available for mailing, comprising 14 printed pages of A3 (twice A4 size) glossy paper on a spiral wire binder. This calendar features the DEPG’s locomotives, both in service and in preservation, with all of the photos being so kindly provided by members and supporters. Click here or on the image above to GET YOUR COPY – WHILE STOCKS LAST – for £14 plus p&p.

ON SHED: last week, we featured Mark Bladwell’s photo taken at Meldon Quarry near Okehampton, Devon, in May of 1975. The loco was D1063 ‘WESTERN MONITOR’ and the railtour was the ‘ATLANTIC COAST EXPRESS’ that ran from Paddington to Meldon Quarry (the extent of the former LSWR route to Plymouth) before returning to Crediton where a pair of Class 25s took the train on to Torrington (beyond Barnstaple) and back to Exeter St Davids. This week, we feature the ‘Rats’ that worked the special over the ‘withered arm‘ of the former LSWR on what must have been a very interesting day out. Many thanks to Mark for sharing his photo with us all.

Class 25 ‘Rats’ 25224 (D7574, leading) and 25161 (D7511) were pictured at Barnstaple Junction, Devon on the 17th May 1975 after working the ‘ATLANTIC COAST EXPRESS‘ railtour from Crediton. The ‘Derby Sulzers’ worked the railtour to Torrington then back to Exeter St Davids where D1063 took over again and returned the special to Paddington. Class 119 DMU set P587 also adds to the picture, taken by Mark Bladwell © CC BY-NC 3.0

DEPG NEWS: the recently-acquired 20-ft ISO containers at Williton were already fitted with lights and power sockets when purchased, but still needed to be connected to the main shed power supply. This work is being carried out by volunteer Richard who has been busy fitting the required safety devices into the containers, with more work to be done in the older containers during the coming weeks. This will be a significant improvement, with bright LED strip lights fitted in each of the containers at long last. Well done Richard !

The local distribution panel was being wired up in one of our recently-acquired 20ft containers by career electrician and DEPG/WSR volunteer Richard at Williton on Saturday 16th November 2024. Photo by Andy Royal © CC BY-NC 3.0

The DEPG is a charity and is run entirely by volunteers, many of whom give both their time and their money to the continuance of work on the locos in the DEPG fleet. If you have been enjoying the roundup for free, have you considered joining us for just £1 a month ? You can then add your name to all of those helping out on the above projects and play your part in the future of our locos for a lot less than the price of a cup of coffee!

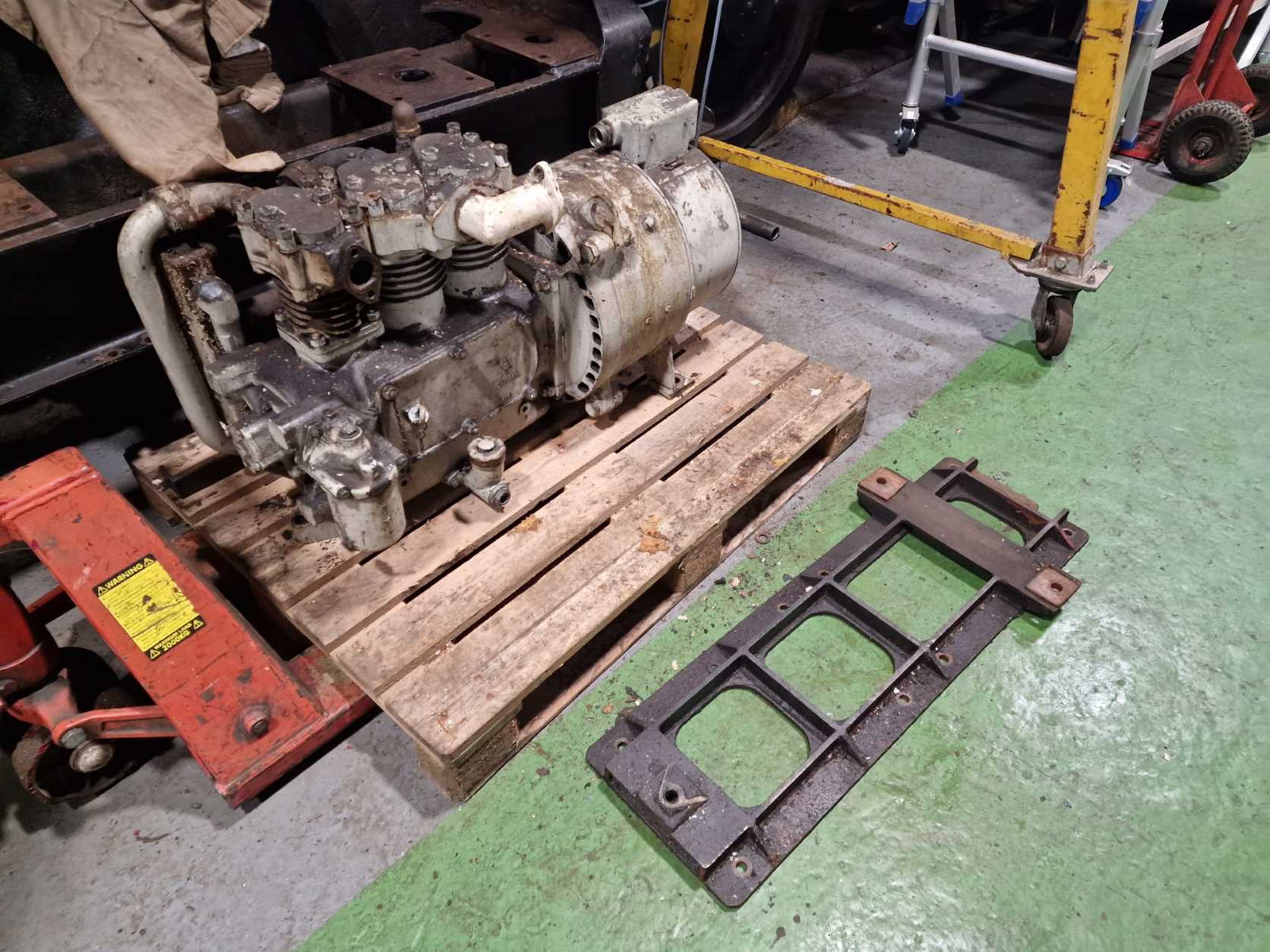

JOIN US using whichever membership class is appropriate for your situation and means. CLICK HERE or on the image below or use the QR code to get the details.

If you would like to go one step further and come along to help with the work on the locos in our fleet, then please use our CONTACT FORM to let us know that you would like to volunteer and we will respond with more details.

We look forward to hearing from you !

Go to the previous Weekly Roundup post