Several former mainline diesel-hydraulics gathered for the Severn Valley Railway’s Magnificent Severn’ event. From left to right, D1062 ‘WESTERN COURIER’, D1013 ‘WESTERN RANGER’ and D1048 ‘WESTERN LADY’ were pictured together at Kidderminster Station on Saturday 30th September 2023. Photo by Geoff Miles © CC BY-NC 3.0

LOCO NEWS:

Class 52 D1010 ‘WESTERN CAMPAIGNER’ – attention has now moved to the input and auxiliary shafts while the findings of the turbine rail disassembly work are being collated for review by the DEPG board. The turbine rail is well protected and remains coated in a film of oil after use, but the other shafts are exposed to the condensation that forms inside the top cover of the transmission and subsequently drips down onto the shafts, getting into the bearings and initiating corrosion during the long periods when the loco is out of use. As we anticipated, these bearings will all need to be replaced and the budget already includes provision for them.

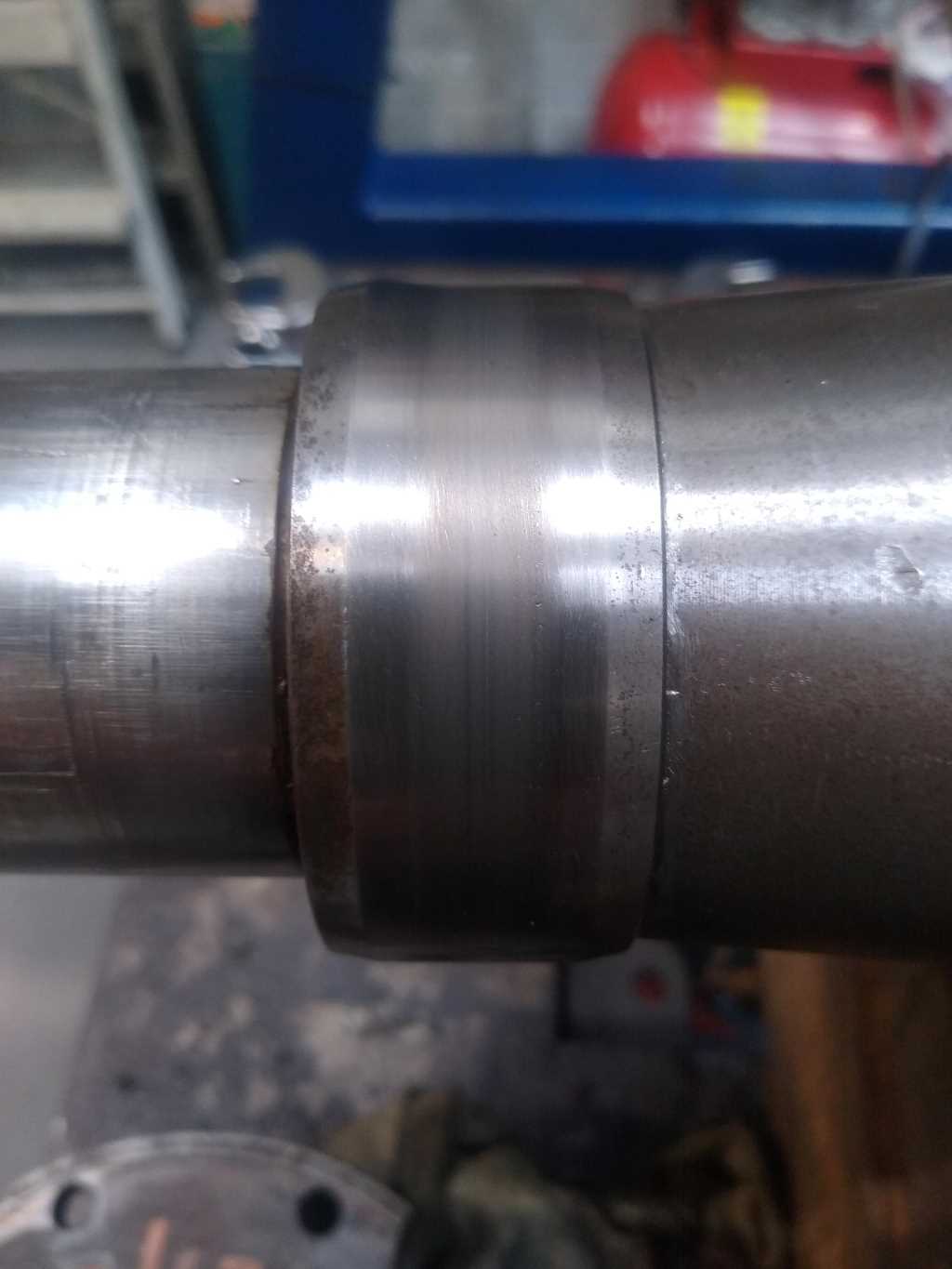

D1010 – the ‘Group 8’ input shaft of the ‘A’ end transmission has now been disassembled. The corrosion damage is self-evident on the inner raceway of bearing 8/30. All such parts will be replaced during the rebuild, but the operating and storage conditions of the loco will need to be revised to minimise the risk of future damage. Pictured at Williton on Tuesday 26th September 2023 by Colin Foxhall © CC BY-NC 3.0

D1010 – the disassembly of the ‘Group 8’ input shaft of the ‘A’ end revealed corrosion damage to all four bearings on this shaft. The damage to bearing 8/42 above is less severe than that affecting bearing 8/30, but is still way past being fit for further use. Pictured at Williton on Tuesday 26th September 2023 by Colin Foxhall © CC BY-NC 3.0

New bearings have also been fitted to the governor assembly (Group 7), which is now fully reassembled and ready for use. A curious finding in this assembly was a thrust bearing (part 7/27) that had been fitted the wrong way around, and had resulted in overheating of the bearing and associated pressure plate (part 7/28). This was easily resolved with a new bearing of the correct type, fitted the right way around !

D1010 – pictured exactly as removed from the governor of the ‘A’ end transmission, the heat damage is evidenced by the blue discolouration of thrust bearing 7/27 and pressure plate 7/28. During the previous overhaul, probably at Swindon Works in the 1970s, this small bearing had been fitted the wrong way around. Pictured at Williton on Monday 18th September 2023 by Colin Foxhall © CC BY-NC 3.0

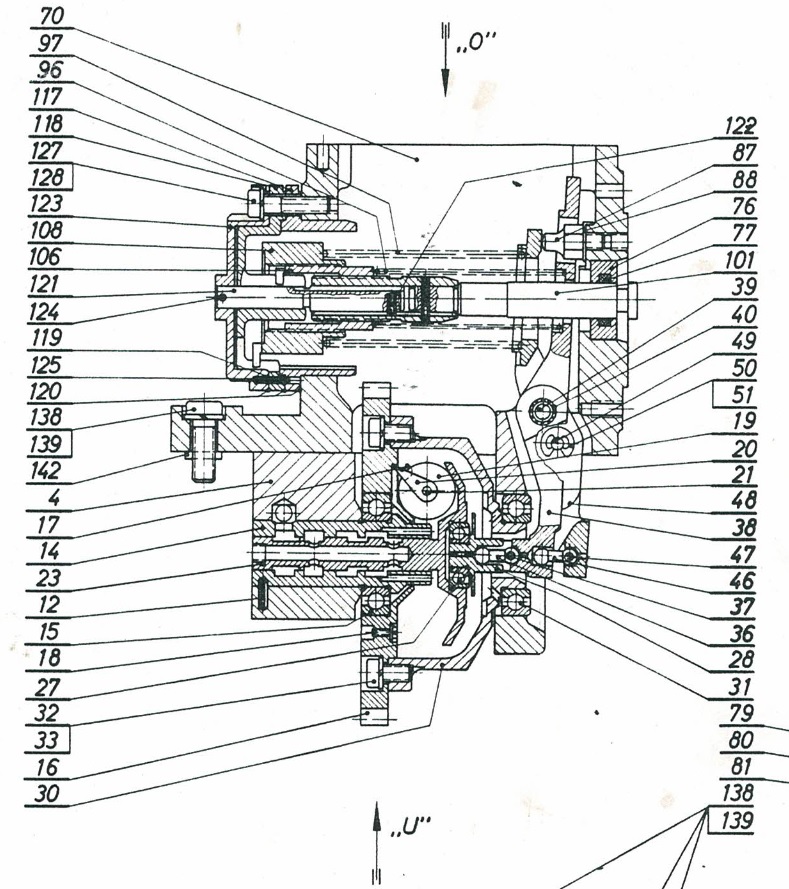

D1010 – the transmission governor fitted to the Class 52s uses the centrifugal force generated by rotating weight(s) 19 to balance the pressure that is generated by pre-set springs (96 and 97) acting through lever arms 38 and 48. The resultant movement allows valve spindle 23 to control the gear selection. Drawing by Voith GmbH © CC BY-NC 3.0

D1010 – the complete governor assembly includes the hydraulic cylinder (yellow) that is fed by the engine-driven hydraulic pump (not shown) and is used to provide feedback to the governor and adjust the gear-change speeds according to the power setting selected by the driver. Pictured at Williton on 18th September 2023 by Colin Foxhall © CC BY-NC 3.0

There are still some patches waiting for sponsors at the ‘B’ end of the loco, so GET IN QUICK TO HAVE YOUR NAME ENGRAVED before the painters reach this end. Many thanks to those who placed their orders during the last few weeks.

Having the loco outdoors has generated an increased interest in our SPONSOR A PATCH scheme, with several more patches being engraved with their sponsor’s names or messages. This initiative remains the single most successful fund-raising activity and has allowed us to make significant progress with the restoration work. PLEASE CONTINUE TO HELP US FUND THIS PROJECT.

Photographs and certificates of sponsorship will be sent out to all who have sponsored the restoration work, but we are still short of volunteer resources and have not yet been able to catch up with this obligation and deliver the documents. Apologies for the delay, we will get it done ASAP. Click the image below to sponsor a patch. Thank you in advance for your support and your patience!

See our CAMPAIGN for CAMPAIGNER web page for more details. We still have a lot of work to do on this massive locomotive, so PLEASE DO COME ALONG AND HELP IF YOU CAN !

Class 33 D6566 (33 048) – this loco is currently stabled at Minehead as the standby locomotive but will return to Williton on Saturday 14th October and will eventually move to Bishops Lydeard in time for ‘WINTERLIGHTS’ duties.

Class 33 D6575 (33 057) – this loco is now stabled at Bishops Lydeard in readiness for an underframe and traction motor examination that will take place during this coming weekend. The loco also needs a brake block change, so the team are going to be busy indeed !

Class 35 ‘Hymek’ D7017 – the electrical fault-finding work has been completed by Neil, John, Ian and Tom and everything checked out OK. This was confirmed during a static engine run and system check at Williton on Saturday 30th September. Click here or on the image below to view a short video clip of the startup.

Class 35 ‘Hymek’ D7017 was started up on Saturday 30th September 2023 to check and confirm the correct operation of the electrical circuity. Video clip by Martin Howard © CC BY-NC 3.0

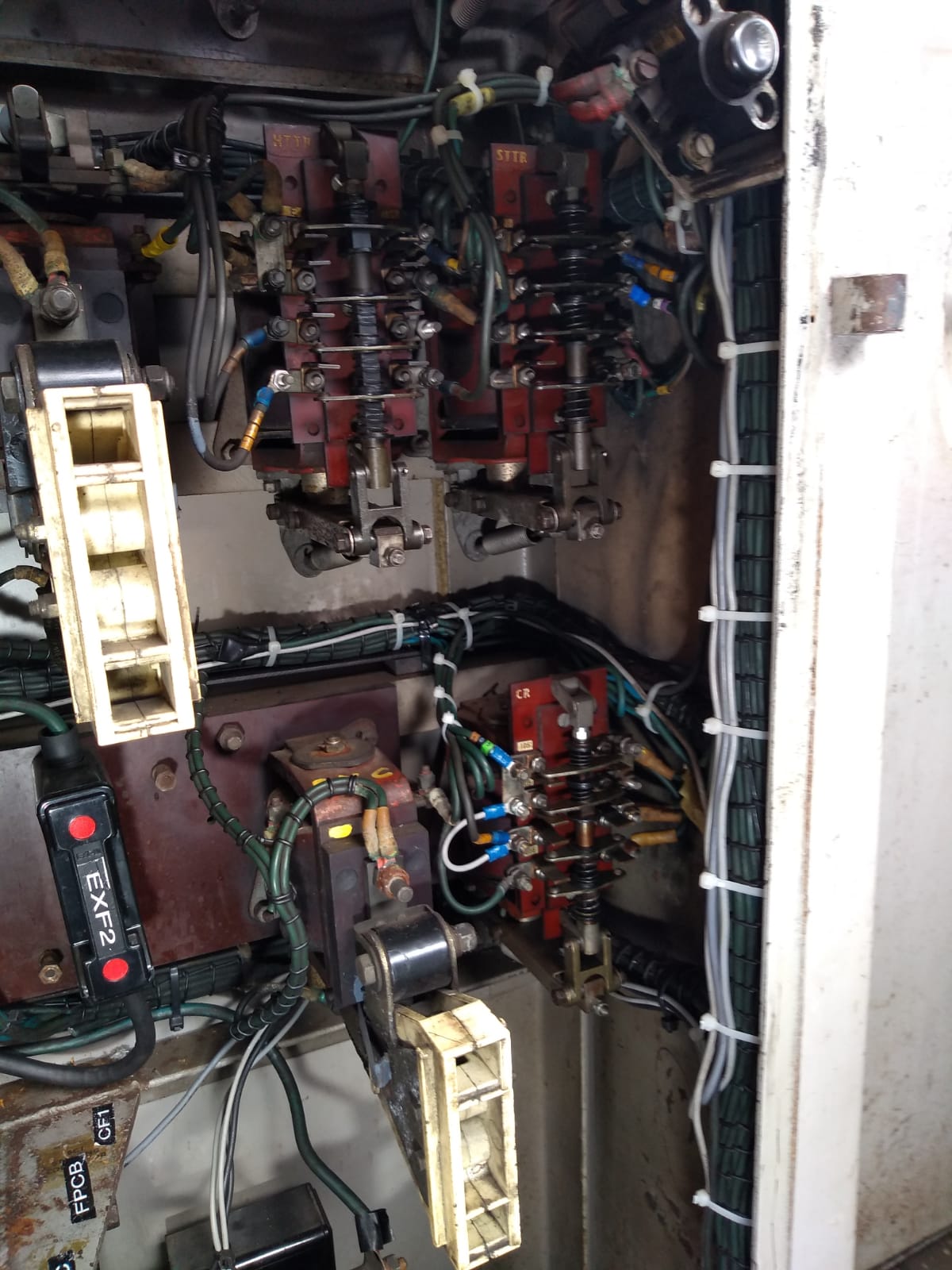

Following the successful static test, Ian finished the electrical work by dressing and securing the wiring in readiness for a formal brake test this coming weekend (or next), and a test run on the WSR, probably during the weekend of 21st October. The finished control cubicle can be seen in the view below:

Electrical work on Class 35 ‘Hymek’ D7017 was completed by Ian R on Sunday 1st October 2023. The control cubicle pictured above shows (clockwise from upper left) the exhauster contactor (white), High Transmission Temperature Relay (HTTR), Shutdown Transmission Temperature Relay (STTR), Converter Relay (CR), another exhauster contactor (white) and the newly-added 100A fuse for the second exhauster (EXF2). Photo by Ian Robins © CC BY-NC 3.0

Class 35 ‘Hymek’ D7018 – this loco has now been towed out of the loco shed to allow work on other locos to take place under cover. The quarantine on this loco has now been lifted but the Root Cause Analysis is still in progress, so the transmission will not be touched until that analytical work reaches the relevant stage. Other work on the loco can now resume.

Class 14 ‘Teddy Bear’ D9518 – work continues on the restoration of the cab assembly and the replacement of the electrical wiring loom that runs inside the driver’s ‘desk’. The Class 14 team is currently sharing its time between this project and the 1000-hour service on sister D9526, so we would welcome additional help to keep both sets of tasks moving along. Just respond to this email if you feel that you could help. Thanks !

This loco is the subject of a fundraising appeal so please follow this link to find out more. We need your help ! In addition to funds, we also need plenty of HANDS. If you love the ‘Teddy Bears’ and you are not already a member of the DEPG, please join us so that you can become one of the team that is going to return D9518 to fully operational condition as ‘NCB No. 7‘.

Class 14 ‘Teddy Bear’ D9526 – this loco is inside the shed at Williton and work is proceeding on the 1000-hour service. The tasks involved with this service are quite invasive and labour intensive, so the work is likely to take several weeks. Upon completion, the loco will move to Bishops Lydeard to cover for Class 09 D4107 (09 019) while that loco undergoes bodywork repairs.

Class 47 47077 ‘NORTH STAR’ – this loco is undergoing a ‘top end’ engine overhaul at Grosmont Works on the North Yorkshire Moors Railway. Work is proceeding well, but the amount of work being done means that the loco is unlikely to emerge for a while yet, but she will be in very good shape for 2024 and beyond.

Andrew Barclay 0-4-0DH 578 – this loco is inside the loco shed and will remain there until the 1000-hour service has been completed on Class 14 D9526.

If you can help by donating your time to any of these projects, then please JOIN US and come along to the depot for an introduction to what we do and how we do it. We currently have people on site from Saturday through to Tuesday and we can open on other days if we can be sure of getting at least two volunteers on site at all times, so there is plenty of scope. We have tasks of all types to suit most capabilities, both skilled and unskilled.

Many thanks to all of our volunteers who give up so much of their time to work on the cleaning, painting, maintaining, restoring, managing and fund raising for our fleet of heritage locomotives !