The progress on this loco has been significant since work started in 2021 and the evidence is clear from the photographs below. When we started work, we didn’t know if we would be able to return D1010 to service or not, because of the seized transmission at ‘B’ end and the lack of available spares. This concern is now behind us and we have two overhauled transmissions, one ready and one close to being ready for re-installation into the loco.

The bodywork repairs were also an area of concern at the start, because of the stressed skin construction and the worries about the need to cut into the loco to remove corroded sections. This was addressed by only making small cuts and repairing the loco patch-by-patch, rather than cutting out large sections – which would have been a lot quicker and easier, but could have been disastrous.

D1010 was shunted onto number 1 road at Williton on 23rd December 2023 to allow D6575 to enter the loco shed for exhaust system repairs. Photo by Tom Courtney © CC-BY-3.0

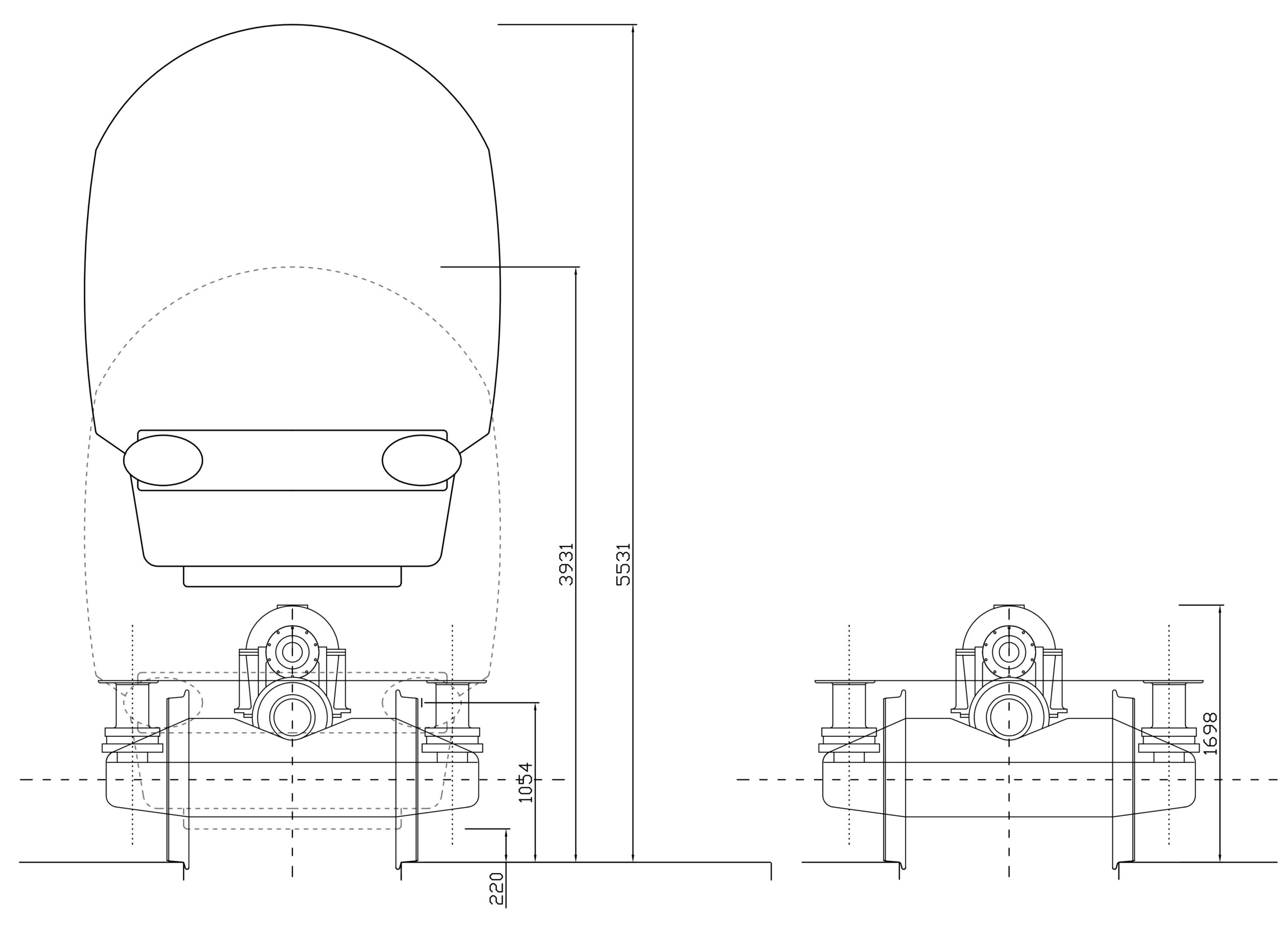

The major challenge now facing us is the bogie overhaul, which cannot be avoided because of the visible wear taking place where an equalising beam pivot has worn and is allowing one of the primary suspension springs to make contact with the bogie frame. The loco was last lifted when in BR service, definitely at Swindon in 1972 but possibly at Laira some time later (we do not have sufficiently detailed records of the Laira days).

To repair the bogies, the loco has to be lifted. This would normally entail positioning the loco over a pit and raising her with jacks. The bogies would then be rolled out and reconditioned bogies rolled in, then the loco would be lowered onto the new bogies, and the job would be completed in a matter of hours. However, without spare bogies being available, the loco could be stuck on the jacks for some considerable time until the bogies had been overhauled. Depending on findings, this could easily be months, blocking the use of the pit and occupying the jacks with no way to change the situation.

The solution being progressed is to lift the loco outdoors using two 100-tonne cranes working in tandem. The loco will still need to go over the pit for the thrust brackets and dampers to be disconnected, then the loco will be positioned outdoors with sufficient space alongside for the cranes to lift the 60-tonne body of the loco, then slew over and place her down on stands. The bogies can then be rolled away for overhaul in the DEPG loco shed and the process reversed when the bogie overhauls have been completed. There are some complications in the details, but this is basically the approach that is being planned.

D1010 needs to be lifted by 1.6m (5′ 3″) to clear the top of the intermediate drive housing that is part of the bogie assembly. Engineering drawings by Barry Quest © CC-BY-3.0

The cost of each lift will be in the region of £6,000 and the cost of repairing the bogies is unknown but expected to be approximately £5,000 each, therefore we need to allocate £22,000 for this activity. This is £10,000 more than was previously allocated to the bogie activities, and has been taken from the contingency allocation. We now need additional funds to allow this work to take place.

Here’s a quick overview of the status of the seven major areas of this project:

- BODYWORK

Some bodywork repairs are still needed above cantrail level (horn enclosures, roof aperture frames, exhaust outlets) but all other repairs have been completed. Filling and sanding is in progress.

- TRANSMISSION

The ‘B’ transmission was completed during June 2023, the ‘A’ transmission was removed from the loco in July 2023 and the overhaul is close to being completed. Both heat exchangers need to be tested. The transmissions will remain out of the locomotive until the bogie work has been completed.

- BOGIES

The method and plan for lifting the loco is close to being finalised. The work will be undertaken at Williton using two cranes. The loco body will be mounted on stands while the bogies are undergoing repair. This is now the key task in terms of timeline.

- COOLER GROUPS

Both cooler groups have been removed from the loco and have been stripped down for cleaning before welding repairs are made. Each radiator element (96 in total) will be cleaned and pressure tested.

- ELECTRICAL SYSTEMS

The ‘B’ cab wiring and switchgear is being serviced and individual wires are being replaced where necessary. Upon completion, attention will move to the ‘A’ cab, then the engine room.

- BRAKING SYSTEM and AIR SYSTEM

The air and brake pipework is being inspected and any corroded lengths of pipework are being replaced. Brake valves are being removed and packed for shipment to a rail-approved contractor for overhaul.

- ENGINES

The ‘A’ engine requires head seal replacement work on three cylinders. The ‘B’ engine is OK and does not need any work done except occasional barring over.

|

Photo by Josh Brinsford © CC-BY-3.0 |

Photo by Andy Royal © CC-BY-3.0 |

|

Photo by Andy Royal © CC-BY-3.0 |

Photo by Andy Royal © CC-BY-3.0 |

|

Photo by Colin Foxhall © CC-BY-3.0 |

Photo by Colin Foxhall © CC-BY-3.0 |

|

Photo by Andy Royal © CC-BY-3.0 |

Photo by Andy Royal © CC-BY-3.0 |

The timeline for the return to service remains dependent on two things – funding and the availability of volunteers. On a locomotive with the size and complexity of a ‘Western’, both are essential elements of this major effort to return D1010 to working order.

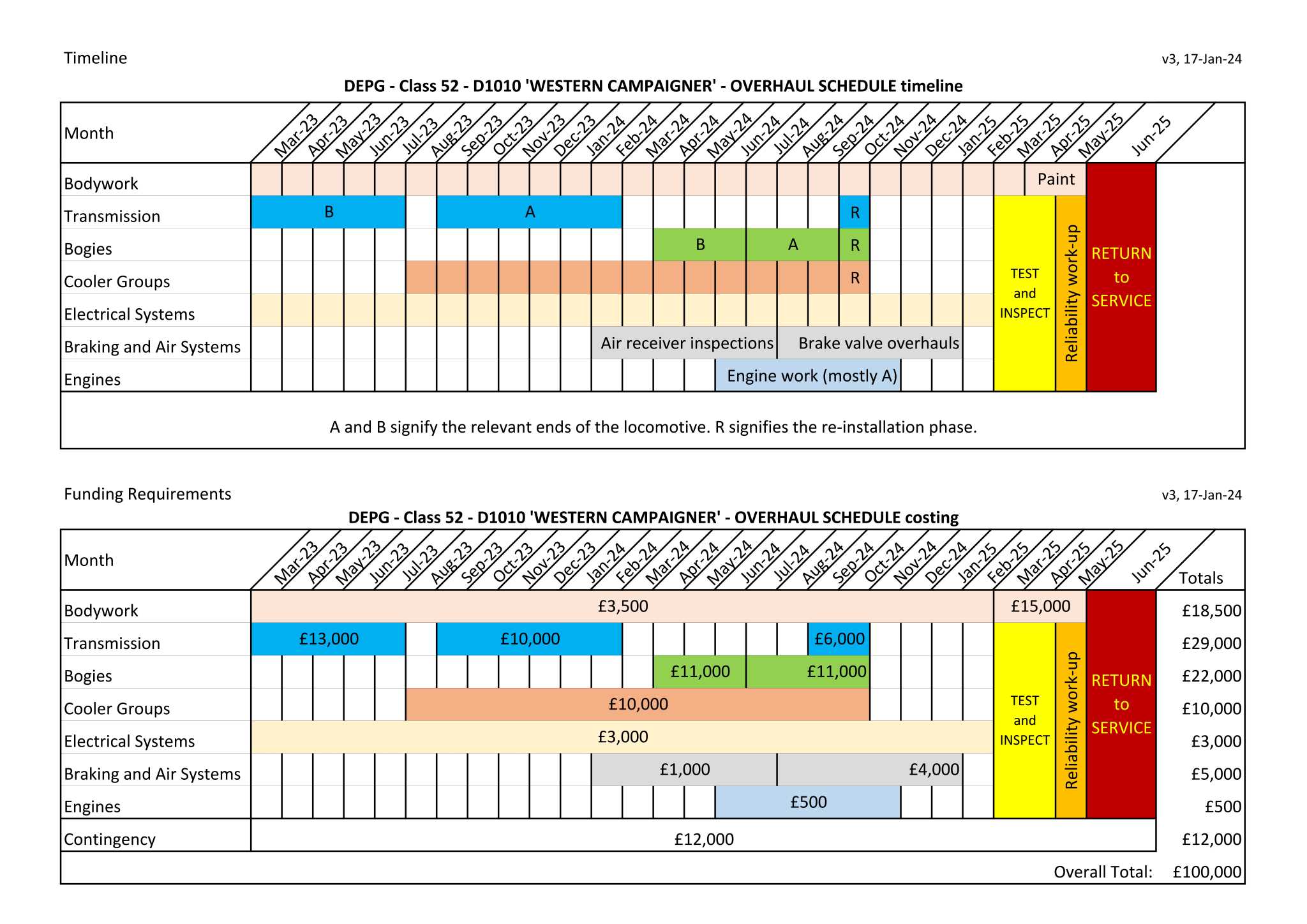

The revised timeline shows what could be achieved if we can maintain a sufficient rate of funding and continue to recruit new volunteers. There is a lot of work to be done to achieve the target date, so please come along and help.

D1010 fundraising update

Our appeal was launched in July 2021 with a target of £100,000 and 30 months later, our fund has reached almost halfway but the rate of growth has slowed to a trickle in recent times, no doubt because of the harsh economic climate that we all find ourselves facing. The updated breakdown of the fund is given in the revised table below (as at 31-Dec-23):

|

Estimated costs and income streams |

Amount £ |

Notes |

|

Bodywork repairs and repainting |

£18,500 |

|

|

Transmission overhauls |

£29,000 |

|

|

Bogie overhauls |

£22,000 |

Up by £10k |

|

Cooler group overhauls |

£10,000 |

|

|

Electrical system repairs |

£3,000 |

|

|

Braking system and air system overhauls |

£5,000 |

|

|

Engine maintenance |

£500 |

|

|

Contingency |

£12,000 |

Down by £10k |

|

TOTAL of OVERHAUL COST ESTIMATES |

£100,000 |

|

|

Donations from members and supporters |

£21,444 |

As at 31-Dec-23 |

|

D1010-related profits from our online store |

£8,379 |

As at 31-Dec-23 |

|

Sponsorship of the transmission repairs |

£12,500 |

Funds received |

|

Sponsorship of the bodyside repairs |

£5,000 |

Funds received |

|

TOTAL |

£47,323 |

As at 31-Dec-23 |

|

Funding to be raised during 2024 |

£52,677 |

|

Many thanks to ALL D1010 restoration fund donors for providing the funding that has allowed us to make so much progress to date.

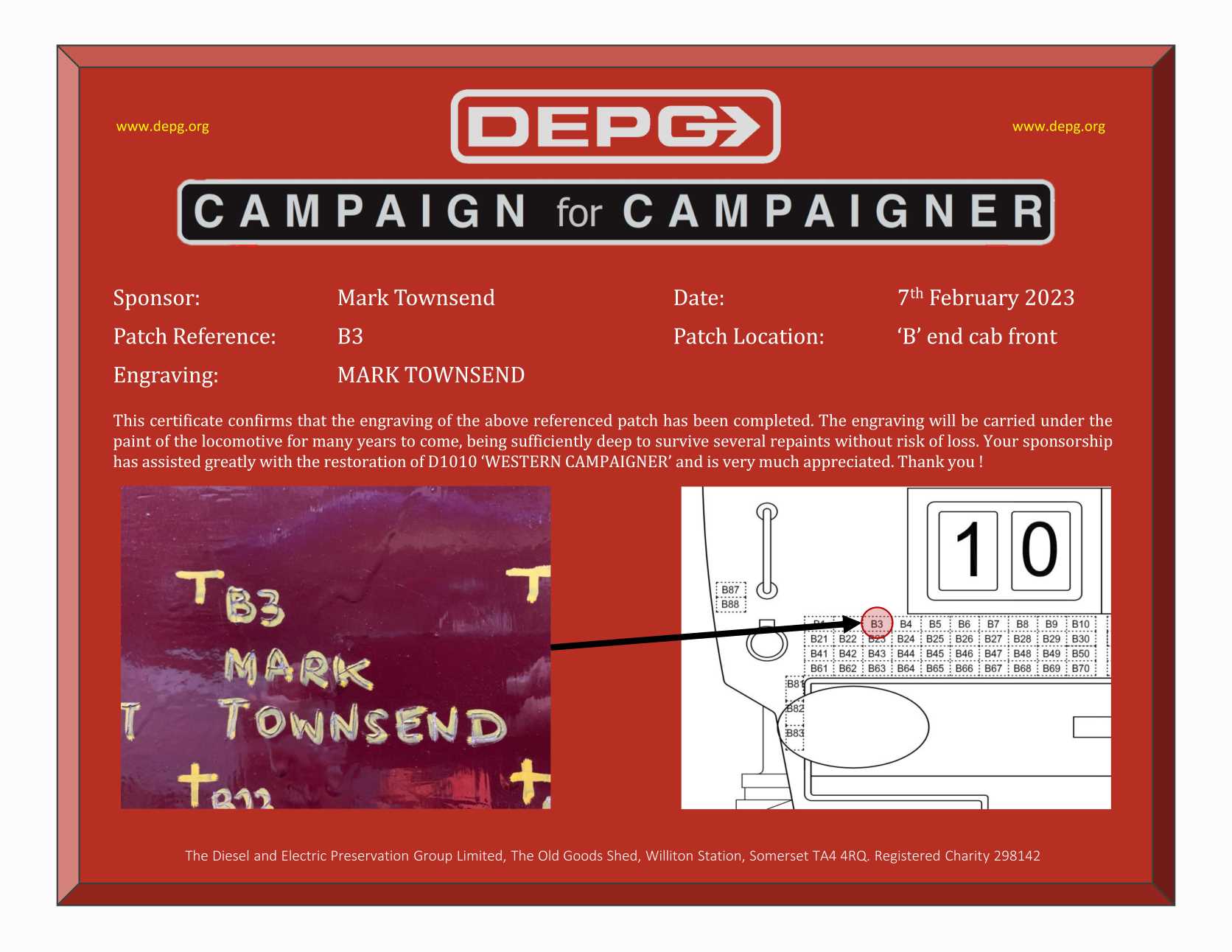

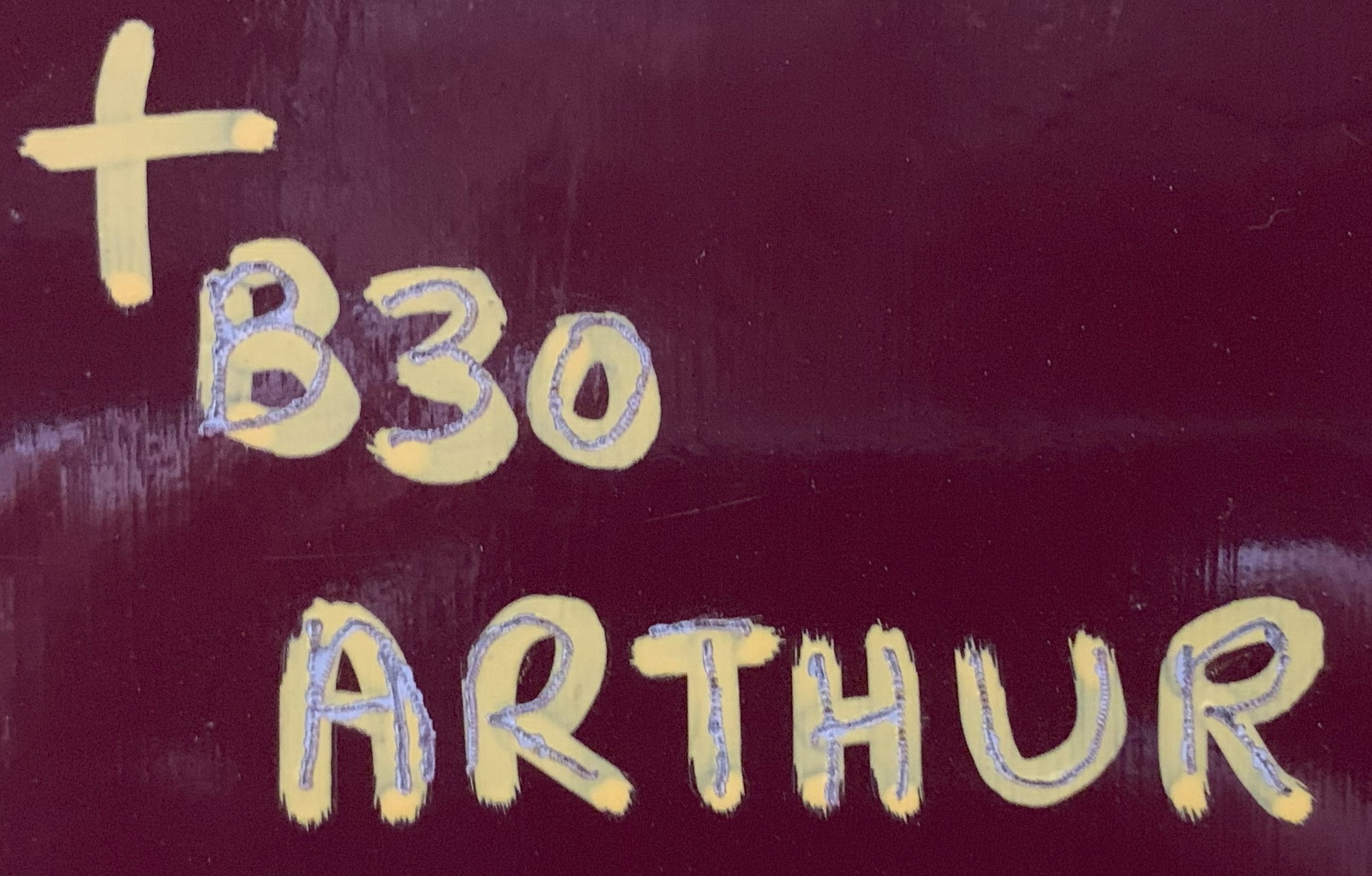

Sponsorships for patches on D1010 continue to come in, for which we are VERY grateful indeed. We have many more patches waiting for sponsors, so please support the CAMPAIGN for CAMPAIGNER and click here or on the image further below to get your name engraved into the metal of the locomotive. We will be having another engraving session as soon as the weather allows.

The certificates are now being emailed to the sponsors – here’s an example of what we are sending out:

The marking process involves the use of an ink pen to allocate a patch number and define the patch boundaries, then the sponsor’s name or chosen message is written using the ink pen. The vibratory engraving tool is then used to trace the marking while making a deep impression into the steel of the patch. The patch is then painted over using multiple coats, but the engraving remains in the metal and will withstand many rubdowns and repaints, in fact it is very difficult to remove (which is how we learned to write the text using the ink pen first!). The engraving will last as long as the metal. Here’s a close-up:

Sponsorship includes a photograph and a certificate via email, but we can print the certificates on photo paper and mail them out upon request, in which case we need to ask for an additional £2.50 donation per certificate to cover photo paper, ink and postage (donate via our website or via Membermojo).

The drawings that have been developed in parallel will provide a formal record of the position of each sponsored patch and this will allow sponsors to look up the location of their patch when they visit the depot at Williton. THANK YOU VERY MUCH FOR YOUR SUPPORT – and your PATIENCE !

Click the image below to sponsor a patch. Thank you in advance for your support (and your patience!).

Details of the work remaining to be done on this restoration project along with a status report of the funding is included in each issue of the DEPG Newsletter, which is distributed to DEPG members on a quarterly basis. A summary will be posted via this website some time afterwards, but JOIN THE DEPG to get the information in more detail and more quickly.

Purchases of D1010-related items from our ONLINE STORE will also assist D1010 because all such profits will be allocated to the D1010 RESTORATION FUND:

-

Book – Hydraulic Memories£17.50 incl VAT excl P&P

Book – Hydraulic Memories£17.50 incl VAT excl P&P -

Replica number plate – D1010£50.00 incl VAT excl P&P

Replica number plate – D1010£50.00 incl VAT excl P&P -

Sponsor a Patch on D1010£25.00 – £40.00

Sponsor a Patch on D1010£25.00 – £40.00 -

Donate £10 to D1010£10.00

Donate £10 to D1010£10.00 -

Coaster – D1010£3.50 incl VAT excl P&P

Coaster – D1010£3.50 incl VAT excl P&P -

Mug – D1010 ‘WESTERN CAMPAIGNER’£7.00 incl VAT excl P&P

Mug – D1010 ‘WESTERN CAMPAIGNER’£7.00 incl VAT excl P&P -

Booklet – D1010 – From Merehead to Minehead£15.00 incl VAT excl P&P

Booklet – D1010 – From Merehead to Minehead£15.00 incl VAT excl P&P -

Cap – D1010 WESTERN CAMPAIGNER£10.00 incl VAT excl P&P

Cap – D1010 WESTERN CAMPAIGNER£10.00 incl VAT excl P&P